Our Infra

Quality measuring instruments :

Vmm, vernier caliper , micro meter, gauges surface tabale, hight guage,

Machineries:

VMC Machine Phillips 1060

The Phillips 1060 VMC is a high-performance vertical machining center designed for precision and efficiency in manufacturing. Known for its robust and rigid construction, it is engineered to handle a wide range of tasks, from rough machining to fine finishing, making it particularly suitable for the die and mold, automotive, and general engineering industries.

STM VL 610 VMC

The STM VL 610 VMC is a compact yet powerful vertical machining center designed for efficient and precise metalworking operations. It features a BT40 spindle capable of speeds up to 10,000 RPM, supported by robust linear guideways for accurate axis movement.

Jyothi RDX 20 VMC

The Jyoti RDX 20 VMC is a specialized vertical machining center engineered primarily for die and mold applications, emphasizing high accuracy and continuous operation. Its robust construction features a broad, rigid base and column made from graded cast iron, designed to effectively dampen vibrations and ensure superior thermal stability.

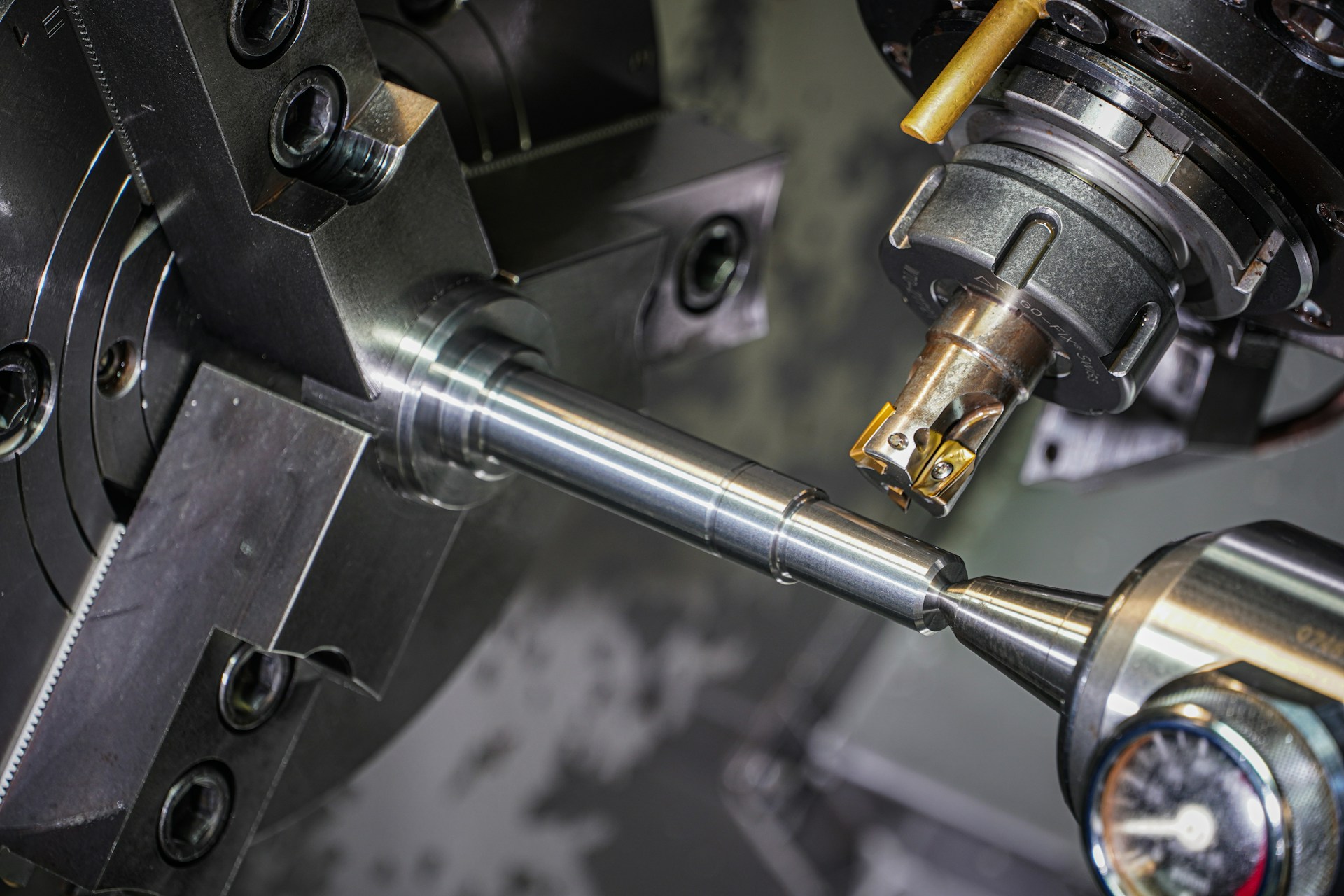

Jyothi DX 200 4B Turning Machine

The Jyoti DX 200 4B Turning Machine is a versatile CNC horizontal turning center designed for high productivity and superior surface finish in various applications. It features a robust construction with a rigid 30° slant bed and a single-piece saddle, ensuring stability for heavy cuts and minimal distortion.

Jyothi DX 200 7B Turning Machine

The Jyoti DX 200 7B Turning Machine is a high-performance horizontal CNC lathe designed for efficient and precise machining of a wide range of components. Building upon the DX 200 series, the '7B' variant typically signifies a longer turning length, offering greater flexibility for producing longer parts. It features a rigid 30° slant bed construction and a robust saddle for stability during heavy cuts and to ensure minimal distortion, resulting in superior surface finishes.

DRAG TIG-400A - Qty 3

The DRAG TIG-400A RELIABLE is a professional-grade AC/DC TIG/MMA welding machine designed for superior performance and durability. It utilizes advanced IGBT inverter technology with a full bridge structure and a digital control system to ensure a stable, high-quality arc. Key features include AC/DC options for welding various materials, high-frequency arc ignition for easy starts, and safety functions like VRD. With a robust 60% duty cycle and a maximum TIG output of 400A, this welder is built to handle demanding industrial and workshop tasks, offering versatility for welding thicknesses up to 10mm.

Quantity - 3

DRAG MIG-402 Machine

DRAG MIG-402 is a high-reliability, multi-functional Inverter welding machine utilizing INVERTER IGBT technology for stable, powerful performance. Designed for MIG/CO2 welding, it offers both constant voltage and constant current output, backed by undervoltage, overvoltage, and current protection. A key feature is its sophisticated arc-ending work mode, which includes a high-voltage slow wire feeding capability to prevent wire explosion at arc striking and minimize small ball removal, significantly easing the operator's burden. Operating on 3PH 415V with a 60% duty cycle at 40°C and a real output of 350A, it reliably handles wire diameters from 0.8-1.2mm. The machine's construction includes multiple insulation materials for circuit protection (Insulation Class F) and comes complete with essential accessories like a wire feeder, air cooling torch, and a CO₂ heated regulator.

DRAG TIG-400P AC/DC Inverter Welding Machine

The DRAG TIG-400P AC/DC is a high-end, trolley-mounted Inverter TIG welding machine (TIG/MMA) featuring INVERTER IGBT and digital control technology for superior performance. It excels in Pulse TIG welding, making it ideal for thin materials, and includes full-featured Pulse TIG parameters and HF stabilizing technology. Operating on 3PH 415V with a strong 60% duty cycle at its 400A output, the unit offers comprehensive control over the entire welding cycle, from Pre-Gas to Slope Down. Standard accessories include a Trolley, water tank, and water cooling TIG torch, providing a powerful, mobile, and water-cooled solution for demanding AC/DC welding applications.

Precision Engineering and Automation Welding Services in Bangalore.

Premier Partner for Manufacturing of Moulds, Fixture and Precision Machining and Expert Welding services

© 2025. All rights reserved. Website Designed and Developed by SCARDO GROUPS

+91- 8150979785 / +91-8861443886

Address

Site No. 79, Sy No 63/3, 21st cross, Muthurayaswamy Layout, Magadi Main Road, Sunkadakatte, Bangalore - 560091

samrudhengineeringweldingservi@gmail.com